Reegz

Epic Member

- Joined

- Jun 24, 2015

- Messages

- 877

- Reaction score

- 214

- Points

- 3,335

I immediately realise the error of ways by asking if anyone works with wood.

Too late.

Anyhoo, I want to build something that I've seen because:-

However, I asked ChatGPT to assist with the dimensions of the wood taking into account the thickness of the wood and I don't seem to agree with what it's saying.

So I'd like to ask a human instead

By my math (which is dodge at best), I'll need the following:-

Help a guy out here

Too late.

Anyhoo, I want to build something that I've seen because:-

- School fees need to be paid very soon

- Would be fun project to do with the kids

However, I asked ChatGPT to assist with the dimensions of the wood taking into account the thickness of the wood and I don't seem to agree with what it's saying.

So I'd like to ask a human instead

By my math (which is dodge at best), I'll need the following:-

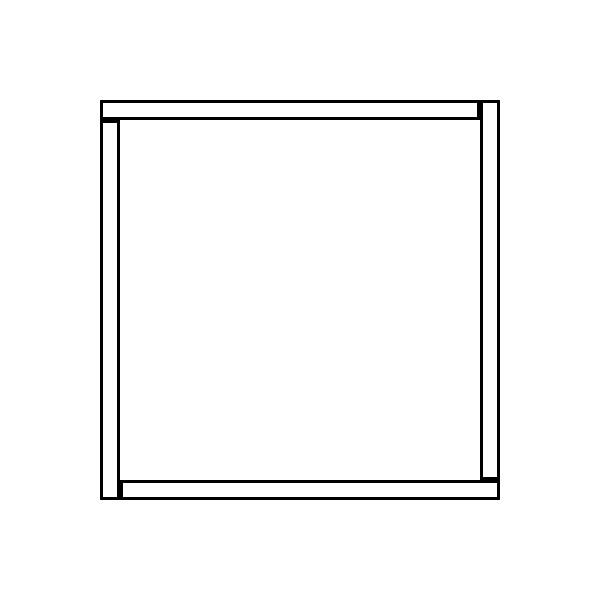

- 2 * 400mm x 400mm -> these will be the opposing sides

- 2 * 360mm x 360mm -> these will be 'top' and 'bottom' sides; they will sit 'inside' hence the 40mm reduction in length to account for its location

- 2 * 400mm x 360mm -> these will cover the remaining open sides. 400mm for the height while the width is 360mm seeing as it is sandwiched between the first two sides

Help a guy out here