keenan

Member

- Joined

- Jan 15, 2013

- Messages

- 29

- Reaction score

- 20

- Points

- 1,185

- Age

- 43

Hello guys.

Allas, after a 7 year hiatus I am back with another "little" project. Please note that this is more about the journey toward the final result than it is about wooing anyone with any sort of skill I definitely don't have

Please do not expect the latest and greatest hardware on the cusp of the silicon high end. As you can see from the case, it's old and dated, but it should make for a pretty clean canvas and a lot of learning along the way..

The main use and purpose of this build will be as an un-intrusive gaming PC fit for the living room.

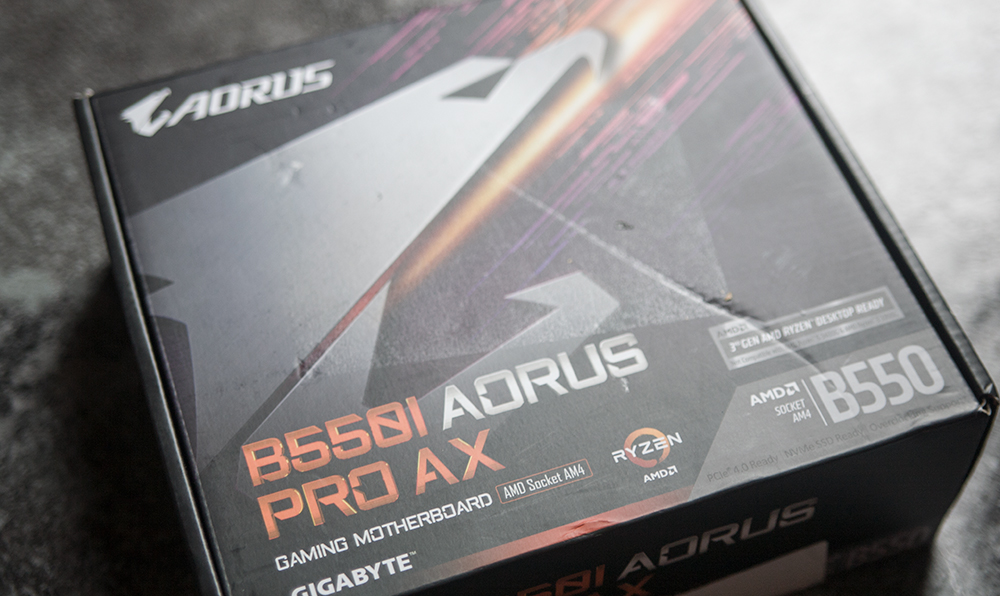

The hardware so far..

A very old and well used Hadron Air from EVG"A". Please refer to the front of the case for an explanation in regards to the emphasized "A"..

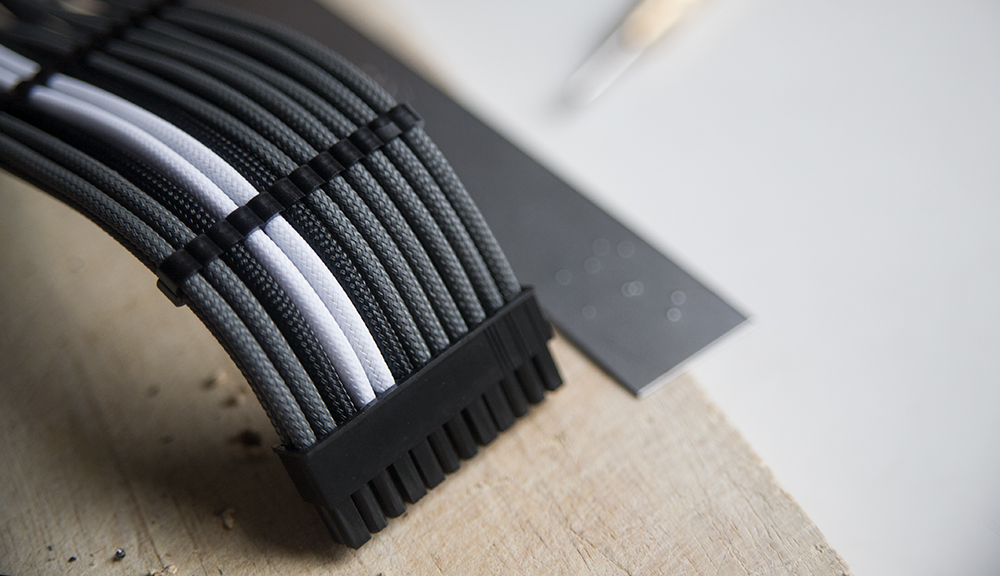

Anywho, I am going to try my best to do a clean, fairly monochrome build that's fully water cooled with 2 X 240 radiators (top and bottom)

Here are some sample photos to get this log going..