Good evening/day all

First, a little laugh at my ignorance, till now I did not know where the "General and Off Topic Discussions" sub-forum had gone since the forum was redesigned. Facepalm.

But, I'm here now and I want to "tweak" my laptop's cooling and so I call upon your combined wisdom...... inb4 repaste/laptop cooling pads/propping the laptop up/cleaning it etc.

So:

-> I'm looking for someone who can recommend/assist with CNC routing services (for copper).

-> I reckon I can get the copper, no problem (but if someone has suggestions as to where/from whom please chip in)

-> Preferably in the Gauteng/JHB area (but if I have to courier back and worth, I will - looking at you @ENDU1997)

-> The heatsink will need to be low-profile - as in < 3mm but, if I have to provide something thicker and then sand it (or something) I'll make a plan (side quests...)

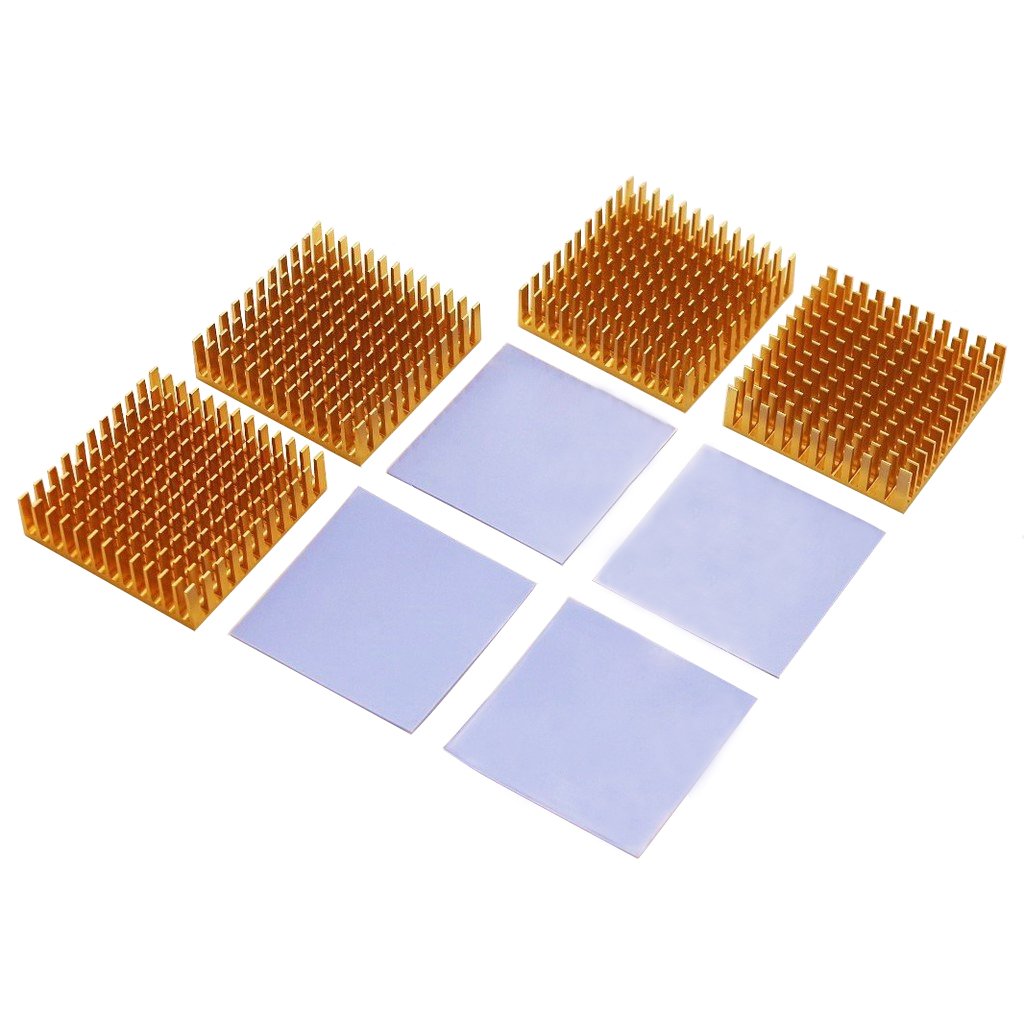

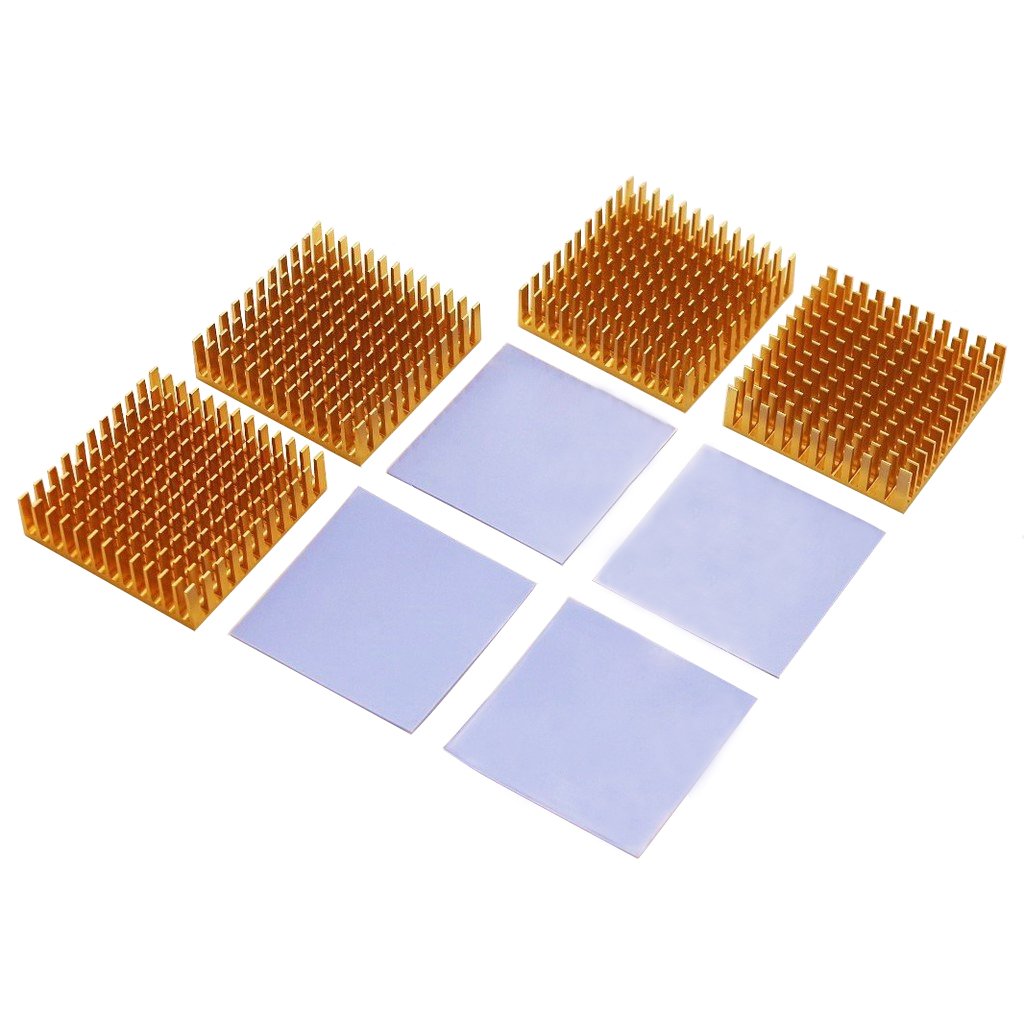

-> Ideally something similar to what is pictured below but with much smaller fins.

-> I'm working on the design/shape and will upload what I have when I'm satisfied with my effort. (if anyone thinks they could put it into AutoCad for me, please give me a shout)

Please, let me know your thoughts!

First, a little laugh at my ignorance, till now I did not know where the "General and Off Topic Discussions" sub-forum had gone since the forum was redesigned. Facepalm.

But, I'm here now and I want to "tweak" my laptop's cooling and so I call upon your combined wisdom...... inb4 repaste/laptop cooling pads/propping the laptop up/cleaning it etc.

So:

-> I'm looking for someone who can recommend/assist with CNC routing services (for copper).

-> I reckon I can get the copper, no problem (but if someone has suggestions as to where/from whom please chip in)

-> Preferably in the Gauteng/JHB area (but if I have to courier back and worth, I will - looking at you @ENDU1997)

-> The heatsink will need to be low-profile - as in < 3mm but, if I have to provide something thicker and then sand it (or something) I'll make a plan (side quests...)

-> Ideally something similar to what is pictured below but with much smaller fins.

-> I'm working on the design/shape and will upload what I have when I'm satisfied with my effort. (if anyone thinks they could put it into AutoCad for me, please give me a shout)

- If there's something I've left out/ more info I ought to provide... please let me know!

- If anyone know where I could get heatpipes locally please let me know.

Please, let me know your thoughts!