Should be all sorted outGood day chaps.

I have an HP Proliant Gen8 Microserver.

Looking to have a caddy or caddies printed for the 2.5" HDD or SSD s.

Scoured the net, cannot find an HP one.

I found this to help 2.5" caddy

I'm in Joburg South & if anyone has been able to print this or has a better design, please let me know.

Oh and what would the costs be?

Thanks

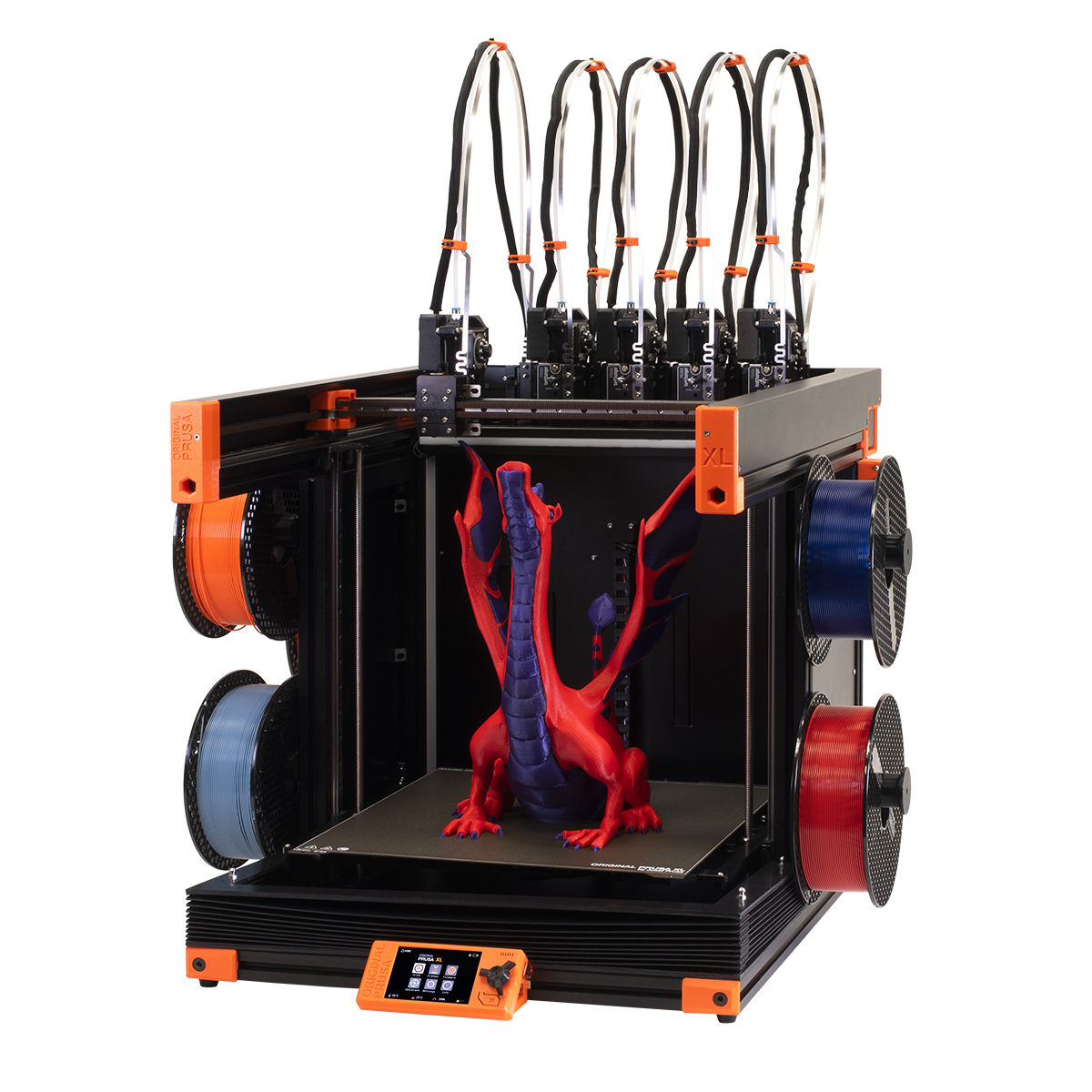

Hey all, just finished building my CoreXY machine (350^3) build volume and I'm struggling with the glass continually cracking, any ideas on what else to use.

The build plate is 350x350, I can't get anything bigger as I designed the printer with basically no tolerances...

Float glass just cracks, aluminium unless milled is going to warp?

Any suggestions?

What brand of glass are you using? How is it attached to the heated bed?Hey all, just finished building my CoreXY machine (350^3) build volume and I'm struggling with the glass continually cracking, any ideas on what else to use.

The build plate is 350x350, I can't get anything bigger as I designed the printer with basically no tolerances...

Float glass just cracks, aluminium unless milled is going to warp?

Any suggestions?

Is it still up and running?I have literally created www.printbed.co.za for this exact reason. Only created it today, so 0 users and 0 posts. Go and be the first

Quick question for the 3D printers here what is the maximum temperature your products (different filaments) can handle?

Celsius please none of that foreign malarkey!

What is the most heat resistant filament to use to achieve this 120 degrees C?All depends on the material type. From 58 degrees to 110 / 120 degrees.

Sent from my iPhone using Tapatalk

What is the most heat resistant filament to use to achieve this 120 degrees C?

I haven't printed in a while, but keen to experiment with something.What is the most heat resistant filament to use to achieve this 120 degrees C?

I suspect they're talking about temps the final part can withstand, not nozzle temp during printing.I haven't printed in a while, but keen to experiment with something.

If you're trying to print at a moerse speed, surely you should put the heat up a little, even above 120?

Because the filament would be moving so fast that it doesn't actually even reach that temp.

@ravingDIODE what do you think?

Indeed - I wanted to know what the failure temperature would be on a printed piece if I were to use it in a high heat environment.I suspect they're talking about temps the final part can withstand, not nozzle temp during printing.

Sent from my VOG-L09 using Tapatalk

That is correct but probably more so is a high flow Hot End ... Like the Mosquito MagnumI haven't printed in a while, but keen to experiment with something.

If you're trying to print at a moerse speed, surely you should put the heat up a little, even above 120?

Because the filament would be moving so fast that it doesn't actually even reach that temp.

@ravingDIODE what do you think?

And I'm being dumb, because PLA melts up to 220 normally, not 120.I suspect they're talking about temps the final part can withstand, not nozzle temp during printing.

Sent from my VOG-L09 using Tapatalk

how can it help me if the bed doesn't self-level? what info can it give me? and how do I apply the acetone? this stuff ? Smith and Co Acetone (500ml)Bltouch is always useful. Acetone vapour to smooth abs prints.

Sent from my SM-G996B using Tapatalk

It helps by probing the bed at multiple points, essentially mapping out the bed in grids for high spots or low spots. It stores the values It gets and uses those value when the nozzle gets to those areas. Beds warp through adjustments, heating and cooling etc. Creality is notorious for shipping warped beds.how can it help me if the bed doesn't self-level? what info can it give me? and how do I apply the acetone? this stuff ? Smith and Co Acetone (500ml)

Thank you so much for these gems. For octoprint: I have a raspberry pi and a webcam. whats next in terms of hardware? What else do I need?It helps by probing the bed at multiple points, essentially mapping out the bed in grids for high spots or low spots. It stores the values It gets and uses those value when the nozzle gets to those areas. Beds warp through adjustments, heating and cooling etc. Creality is notorious for shipping warped beds.

Using something like Octoprint can give you a visual representation of your bed level as well, with a heat map of sorts identifying low and high areas.

Is it gimmicky? I don't think so. It works and is rather good at laying down that first print consistently. Can you do without? Sure. Lots of ways. Glass bed helps. Mesh bed leveling in firmware. Figuring out low spots and slapping some paper under the magnetic build surface. Constant trial and error and fiddling with those damn knobs. The BLTouch takes away much of the headaches. Also, its so damn cheap which makes it a no-brainer. Anything cheap, mod wise, that makes your 3D printing life easier definitely helps.

The acetone isn't applied to the ABS prints as such. This should help explain :

USB cable and you're all setThank you so much for these gems. For octoprint: I have a raspberry pi and a webcam. whats next in terms of hardware? What else do I need?

Well since were going at it with the QNA do you use a dry box? FilaTank Vacuum Sealed Container | Filament Preservation I found this but almost 200 bucks for Tupperware seems spensive. Better solution?USB cable and you're all set

If you're going the BLTouch route, make sure to get up to speed on how to flash the latest Marlin firmware with the BLTouch option enabled.

Nope. Don't use one. Probably should considering the humidity in CT. I have occasionally (rarely) popped filament in to the oven to 'dry' but for the most part never needed to. Also, I guess it can be brand specific. Some brands just all out suck and often times you troubleshoot the hardware when the filament is at fault.Well since were going at it with the QNA do you use a dry box? FilaTank Vacuum Sealed Container | Filament Preservation I found this but almost 200 bucks for Tupperware seems spensive. Better solution?